Reverse Logistics: Unveiling Hidden Profits in Returns Management

Reverse logistics, a critical yet often overlooked aspect of supply chain management, is revolutionizing how businesses handle returns and recapture value. This strategic approach to managing the backward flow of products from consumers to manufacturers is not just about processing returns; it's about transforming a traditionally costly operation into a profit center and competitive advantage.

The Evolution of Reverse Logistics

Reverse logistics has come a long way from its origins as a necessary evil in retail operations. Historically, returns were viewed as a cost center, with businesses focusing primarily on minimizing expenses associated with processing and disposing of returned items. However, as e-commerce boomed and consumer expectations shifted, forward-thinking companies began to recognize the potential of reverse logistics as a strategic asset.

The transformation of reverse logistics from a back-office function to a core business strategy has been driven by several factors. Advancements in technology, such as RFID tracking and data analytics, have enabled businesses to gain unprecedented visibility into the returns process. This visibility has allowed for more efficient sorting, faster processing times, and better decision-making regarding the disposition of returned goods.

Maximizing Value Recovery

One of the most significant advantages of a well-executed reverse logistics strategy is the ability to maximize value recovery from returned products. This process involves several key steps:

-

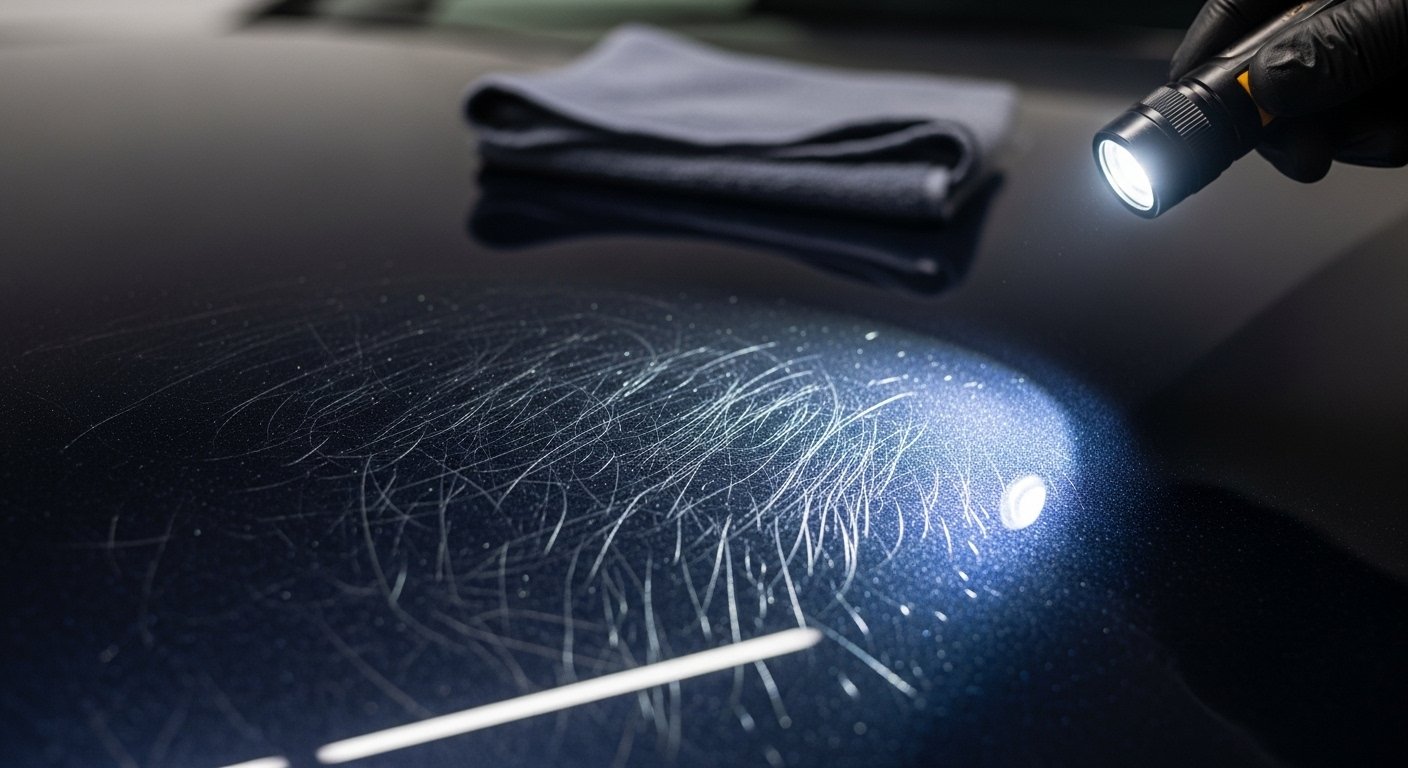

Rapid Assessment: Quickly determining the condition of returned items to make informed decisions about their fate.

-

Refurbishment and Repair: Restoring products to sellable condition, often at a fraction of the cost of manufacturing new items.

-

Resale Channels: Identifying and leveraging appropriate secondary markets for refurbished or slightly used goods.

-

Parts Harvesting: Salvaging components from irreparable items for use in repairs or new product manufacturing.

-

Recycling: Properly disposing of unsalvageable materials in an environmentally responsible manner.

By implementing these steps, companies can reclaim a significant portion of the value that would otherwise be lost in the returns process. This not only improves profitability but also contributes to sustainability efforts by reducing waste and extending product lifecycles.

Customer-Centric Returns Policies

A key component of successful reverse logistics is the development of customer-centric returns policies. These policies go beyond simply accepting returns; they aim to create a positive customer experience that builds loyalty and encourages repeat business. Some innovative approaches include:

-

Easy-to-understand return policies that remove friction from the process.

-

Offering multiple return options, such as in-store returns for online purchases.

-

Providing pre-paid return labels to simplify the shipping process for customers.

-

Implementing hassle-free, no-questions-asked returns for certain product categories.

-

Offering instant refunds or store credit to expedite the returns process.

By focusing on customer satisfaction in the returns process, businesses can turn a potential point of frustration into an opportunity to strengthen customer relationships and differentiate themselves from competitors.

Leveraging Data for Continuous Improvement

The wealth of data generated through reverse logistics operations presents a valuable opportunity for businesses to gain insights and drive continuous improvement. By analyzing return patterns, reasons for returns, and product performance, companies can:

-

Identify and address quality issues in manufacturing or design.

-

Refine product descriptions and marketing materials to set accurate customer expectations.

-

Optimize inventory management and demand forecasting.

-

Improve packaging to reduce damage during shipping.

-

Develop targeted customer education initiatives to reduce returns due to user error.

This data-driven approach allows businesses to not only improve their reverse logistics operations but also enhance their overall product lifecycle management and customer experience strategies.

The Role of Technology in Reverse Logistics

Advancements in technology are playing a crucial role in transforming reverse logistics from a cumbersome process to a streamlined, value-adding operation. Key technological innovations include:

-

Artificial Intelligence and Machine Learning: These technologies are being used to predict return likelihood, optimize routing, and automate decision-making in the returns process.

-

Internet of Things (IoT): Connected devices and sensors provide real-time tracking and condition monitoring of returned items.

-

Blockchain: This technology enhances transparency and traceability in the reverse supply chain, particularly useful for high-value or regulated products.

-

Robotic Process Automation (RPA): Automated systems are streamlining repetitive tasks in returns processing, increasing efficiency and accuracy.

-

Advanced Analytics: Sophisticated data analysis tools are helping businesses derive actionable insights from their reverse logistics operations.

By leveraging these technologies, companies can significantly improve the speed, accuracy, and cost-effectiveness of their reverse logistics operations.

Strategic Insights for Optimizing Reverse Logistics

• Conduct a thorough cost-benefit analysis of your current returns process to identify areas for improvement.

• Invest in employee training to ensure consistent and efficient handling of returns across all channels.

• Consider partnering with specialized third-party logistics providers to leverage their expertise and infrastructure.

• Implement a robust quality control process for refurbished items to maintain brand integrity.

• Develop a strategy for liquidating unsellable inventory to recoup some value and free up warehouse space.

In conclusion, reverse logistics represents a significant opportunity for businesses to transform a traditional cost center into a source of value creation. By adopting a strategic approach to returns management, companies can improve customer satisfaction, reduce operational costs, and contribute to sustainability efforts. As consumer expectations continue to evolve and environmental concerns grow, mastering reverse logistics will become increasingly critical for businesses seeking to thrive in the competitive landscape of the future.