Harnessing Heat: The Untapped Potential of Thermoelectric Generators in Automotive Design

In the relentless pursuit of efficiency, automotive engineers are turning their attention to an often-overlooked resource: waste heat. Imagine a world where the scorching temperatures of your car's exhaust system could be transformed into usable electricity, powering your vehicle's accessories and reducing fuel consumption. This isn't science fiction; it's the promising reality of thermoelectric generators in automotive applications.

The Science Behind Thermoelectric Generation

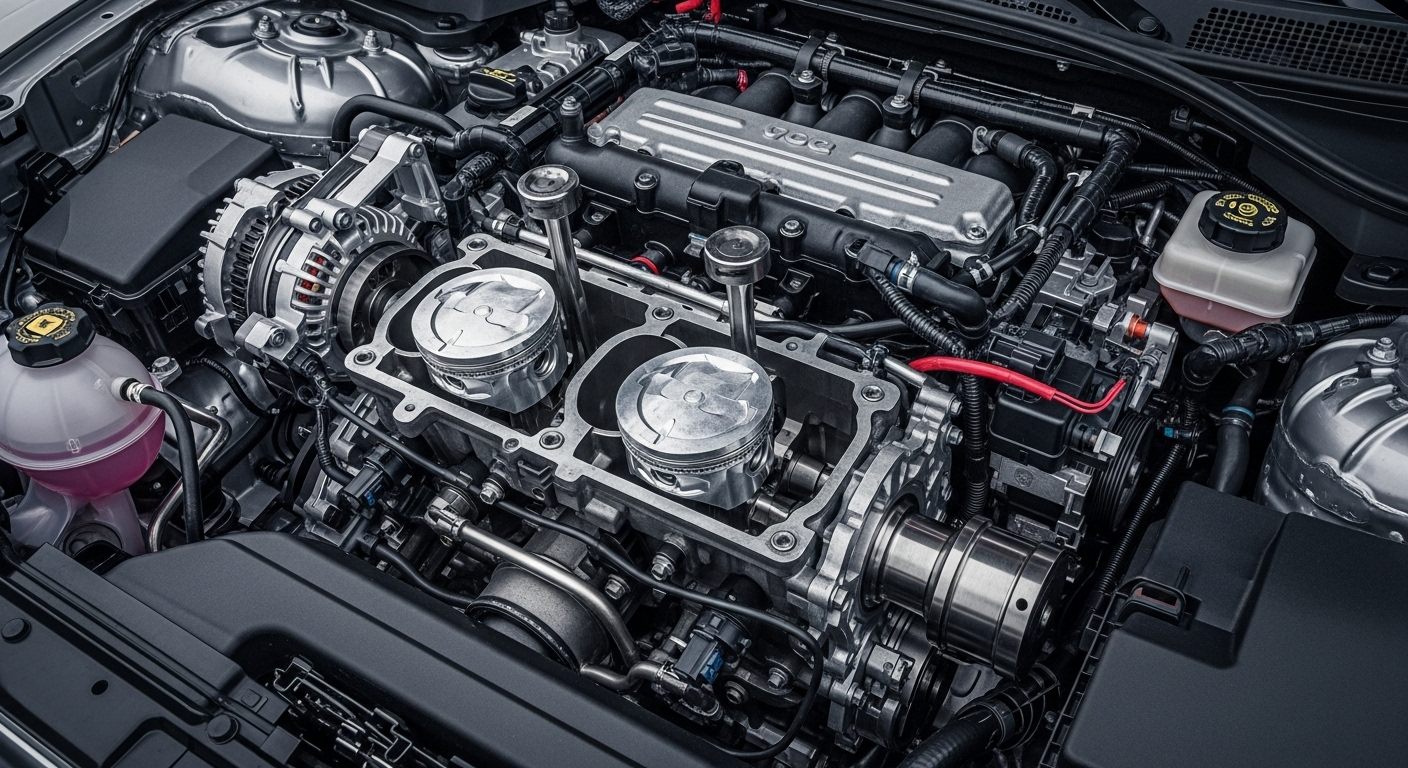

Thermoelectric generators operate on the Seebeck effect, a principle discovered in the early 19th century. This phenomenon occurs when a temperature difference between two dissimilar electrical conductors or semiconductors produces a voltage difference between the two substances. In the context of automotive applications, TEGs consist of arrays of thermocouples that convert temperature differentials directly into electricity.

The beauty of TEGs lies in their simplicity and lack of moving parts. Unlike traditional generators, they require no maintenance and can operate silently and continuously as long as a temperature gradient exists. This makes them ideal for integration into vehicle exhaust systems, where they can harness the heat that would otherwise be lost to the environment.

From Concept to Reality: Implementing TEGs in Vehicles

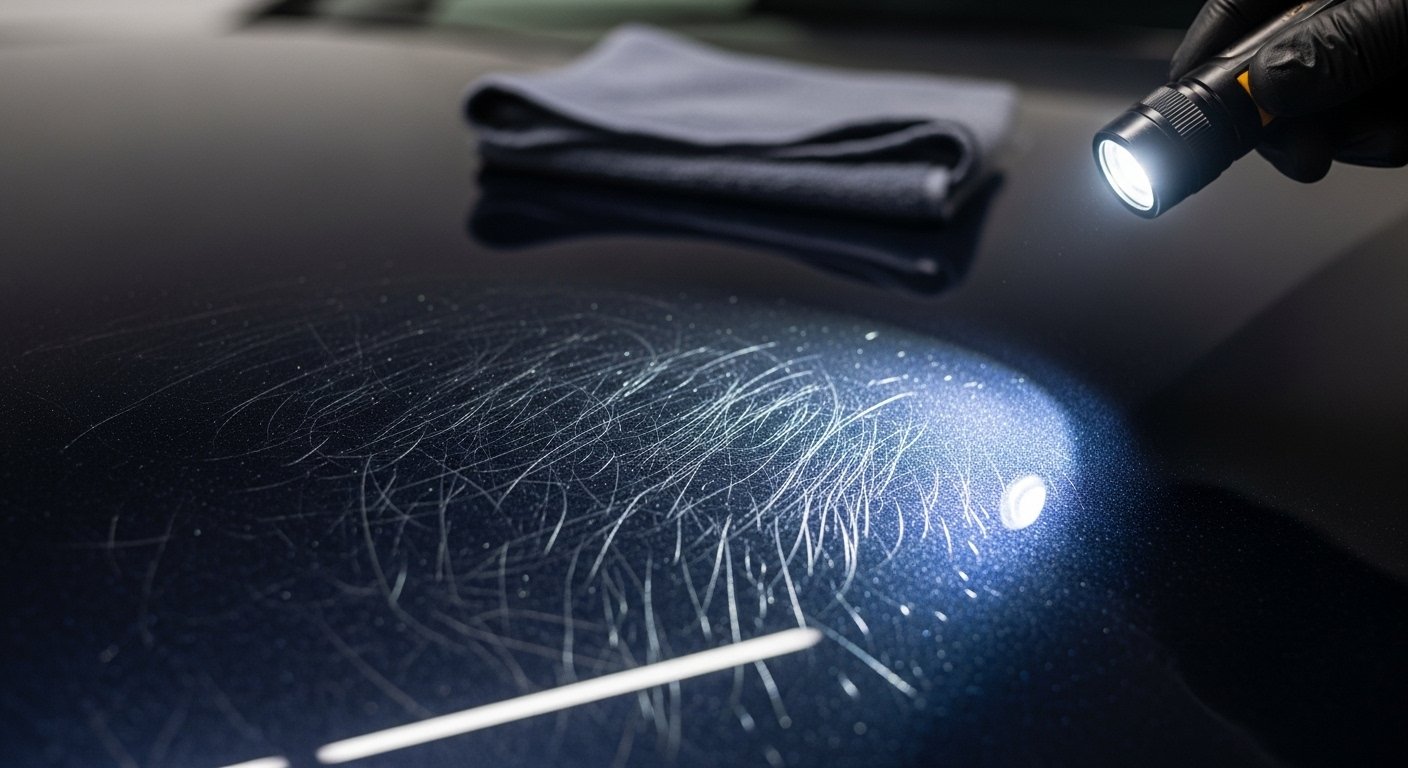

The implementation of thermoelectric generators in vehicles is not without its challenges. Engineers must consider factors such as the optimal placement of TEGs, the materials used in their construction, and the integration with existing vehicle systems. The exhaust system presents an ideal location, as it offers the highest temperature differential between the hot exhaust gases and the cooler ambient air.

Materials science plays a crucial role in the development of effective TEGs. Researchers are exploring advanced semiconductors and nanostructured materials to improve the efficiency of thermoelectric conversion. Bismuth telluride has been a popular choice for its relatively high figure of merit, but newer materials like skutterudites and half-Heusler alloys show promise for high-temperature applications typical in automotive exhaust systems.

The Ripple Effect: Benefits Beyond Fuel Efficiency

While the primary goal of incorporating TEGs into vehicles is to improve fuel efficiency, the benefits extend far beyond reduced fuel consumption. By generating electricity from waste heat, TEGs can potentially reduce the load on the vehicle’s alternator, leading to decreased mechanical losses and improved overall engine performance.

Moreover, the electricity generated by TEGs can be used to power various vehicle accessories, from infotainment systems to climate control. This redistribution of power demand can lead to a more balanced and efficient electrical system within the vehicle. In hybrid and electric vehicles, TEGs could contribute to extending battery range by providing an additional source of electrical energy.

Overcoming Hurdles: Challenges in Widespread Adoption

Despite their potential, thermoelectric generators face several obstacles on the road to widespread adoption in the automotive industry. One of the primary challenges is the relatively low efficiency of current TEG systems. While advancements in materials and design have improved performance, the conversion efficiency of TEGs still lags behind that of traditional generators.

Cost is another significant factor. The materials used in high-performance TEGs can be expensive, and the manufacturing processes are not yet optimized for mass production. Automotive manufacturers must weigh the potential fuel savings against the increased production costs to determine the viability of integrating TEGs into their vehicles.

The Road Ahead: Future Developments and Potential Applications

As research in thermoelectric materials and systems continues to advance, the future of TEGs in automotive applications looks increasingly promising. Improved materials with higher figures of merit could dramatically increase the efficiency of these systems, making them more attractive to manufacturers and consumers alike.

Beyond passenger vehicles, TEGs could find applications in commercial trucking, where long-haul journeys and high fuel consumption make energy recovery particularly valuable. The technology could also be adapted for use in other heat-intensive industries, such as manufacturing and power generation, further expanding its impact on energy efficiency across various sectors.

In conclusion, thermoelectric generators represent an exciting frontier in automotive engineering. By harnessing the power of waste heat, these devices have the potential to improve vehicle efficiency, reduce emissions, and pave the way for more sustainable transportation solutions. As the technology continues to evolve, we may soon see a new generation of vehicles that are not only more efficient but also more environmentally friendly, thanks to the innovative application of thermoelectric principles.